Hugard Inc. makes precision turned parts. In order to maximize production efficiency, they designed custom part catchers that collect parts as they are parted off of the lathe.

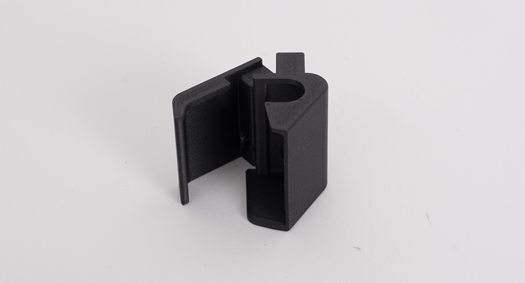

Hugard Inc. uses a custom claw as a parts collector to catch precision turned parts as they’re parted off by a CNC lathe. Because the parts are both extremely complex and subject to a constant stream of corrosive cutting fluid, they’re unsuitable for CNC Milling and conventional ABS 3D printing. Markforged’s ability to create uniquely robust, geometrically complex parts allowed Hugard to achieve massive savings.

Each part of the gripping system catches 3,000 parts per day and operates 24/7.

PRECISION MACHINES — Hugard Inc. uses a fleet of CNC lathes to make micro precision turned parts.

PROCESS AUTOMATION — They use a custom gripping fixture to catch and remove parts as they finish.

ROBUST PART — Onyx and Carbon Fiber provide the strength and cutting fluid resistance to survive.

MASSIVE SAVINGS — Hugard Inc. prints grippers 16x cheaper and 25x faster with Markforged technology.