Reliable composite materials for every stage in the production cycle.

Composite Materials for 3D Printing

What is a composite?

Composites are parts made up of more than one material that, when combined, have synergistic properties different from the original materials. There are two main

components of composite parts: a matrix and a reinforcement.

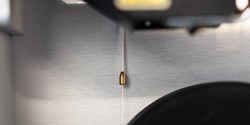

What is CFF?

Continuous Filament Fabrication (CFF) is the method with which fiber reinforced composites are 3D printed. Continuous fibers are extruded layer-by-layer similarly to FFF processes.

What types of composite materials can Markforged use for 3D printing?

Markforged offers four reinforcement fibers: carbon fiber, fiberglass, Kevlar, and HSHT fiberglass.

Can I print using only fibers?

Just as carbon fiber are always laid with a matrix, so are our fibers. Our reinforcement fibers are 3D printed with Onyx during the printing process to ensure optimal mechanical properties, accuracy, and surface finish.

Check out the Material Datasheet for a complete overview.

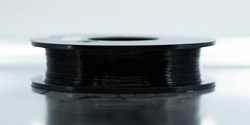

Onyx Filament

Plastic materialNylon mixed with chopped carbon fiber offers a high-strength thermoplastic with excellent heat resistance, surface finish, and chemical resistance.

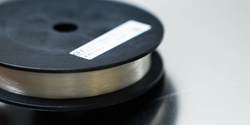

Carbon fiber

ReinforcementOur stiffest, strongest fiber with the highest strength-to-weight ratio.

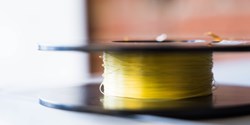

Fiberglass Filament

ReinforcementInexpensive and 11 times stiffer than ABS, fiberglass is the perfect entry-level fiber for 3D printing.

HSHT Fiberglass Filament

ReinforcementHSHT fiberglass material delivers the highest impact resistance and heat deflection temperature of our continuous fibers.

Kevlar Filament

ReinforcementKevlar® is tough, lightweight material, and can bend further than any other fiber, making it ideal for 3D printing.