See how customers are improving their manufacturing workflow with 3D printing.

Hugard Inc. - Ease In Automation

Hugard Inc. makes precision turned parts. In order to maximize production efficiency, they designed custom part catchers that collect parts as they ar...

Read more

Arrow Global - Manufacturing Workholding

The Mark Two helps Arrow Global expand their heavy duty prototyping process with inexpensive, strong 3D printed parts.

Read more

Dixon Valve - A New Paradigm

Dixon Valve prints jaws that mount on a robot that transfers fittings between machining centers.

Read more

Humanetics - Next Day Molds

Humanetics uses a Markforged X7 to print molds for thermoset plastics. Each mold must withstand significant clamping force while heated to 220 F.

Read more

Radiant Images - Multibody Construction

Radiant Images prints the entire frame of the AXA 360 camera rig with Markforged. The frame consists of high strength printed polygonal brackets bolte...

Read more

JJ Churchill - Precision Quality Inspection

JJC can design and test fixtures within the same week, with lower material waste and exceptional quality and precision.

Read more

Arc34 - Versatile GoPro Mount

Arc34 Uses continuous Fiberglass and Chopped Carbon Fiber to manufacturing end use GoPro mounts. Their low volume and high strength requirements make ...

Read more

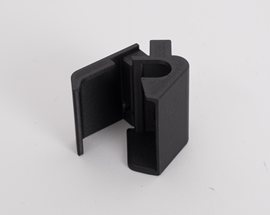

ProCobots - Custom Robotic End Effectors

ProCobots streamlines its customers’ manufacturing workflows by minimising overhead and maximising effectiveness.

Read more

Haddington Dynamics - 3D Printed 7-Axis Robotic Arm

Haddington Dynamics 3D prints the majority of its Dexter robot arm, reducing the number of parts from 800 to less than 70.

Read more

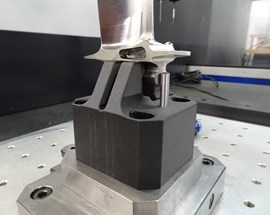

Lean Machine CNC - 3D Printed Vise and Soft Jaws

Lean Machine combined over two dozen continuous carbon fiber reinforced parts with off-the-shelf components for their durable vise and soft jaws

Read more