Some cases the printed part might require improvements in order to succeed. Using our in-house machining capability we are able to offer the below hardware integrations. Check out our machining capabilities here.

Threads and inserts

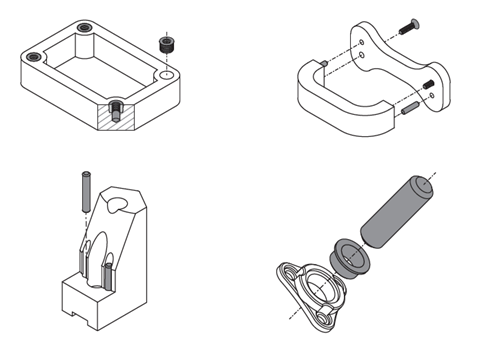

Instead of printing or tapping threads into plastic, add a metal heat-set insert where you need threads. These inserts get pressed in with a soldering iron to reflow the plastic around the part for local isotropic strength. Inserts are stronger and last longer than printed or tapped plastic threads.

Alignment

Use pressed-in dowel pins or shoulder bolts to precisely align multiple components. Press-fit dowel pins are used to line up this handle with its baseplate, while screws secure it. Use dowel pins for alignment before glueing or bolting the components together to attach multiple printed parts precisely.

Concentrity

Bushings or sleeve bearings like the ones inserted into this bracket provide high cylindrical precision and smooth concentric clearance fits. Off-axis loads distribute to the printed part with the bushing’s larger surface area. The bushing cavity can be reinforced with continuous strand composite fibers for higher torsional resistance.