While production refers specifically to converting raw materials into parts, assembly involves putting parts together into final products. Assembly is achieved through automated processes, manual labor, or a combination of both. Optimization of the assembly stage leads to massive cost savings while inefficiencies can wreak havoc on the bottom line.

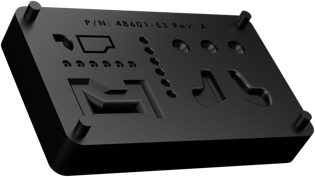

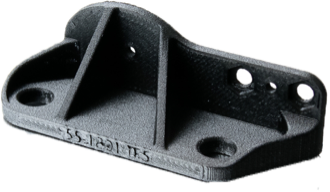

Additive manufacturing can be used to supplement both manual and automated assembly, increasing throughput while decreasing costs. Custom parts for automated systems (such as end-effectors) are traditionally costly and may take weeks to get through a machine shop queue. Markforged 3D printers offer a way to fabricate such hardware with far less skilled labor, decreasing the necessary effort to ramp up an automated assembly line. You can also optimize manual processes with 3D printed assembly tools and fixtures. While conformal geometries that ensure accurate, repeatable assembly prove difficult to fabricate using traditional methods, Markforged 3D printers can produce complex shapes with the mechanical properties necessary for a factory environment.